Warehouse labor costs are a major part of operational expenses, often reaching up to 65%. This article explains strategies to lower these costs while boosting efficiency, including automation, layout optimization, and employee training.

Key Takeaways

- Understanding and managing warehouse labor costs, which account for 60-65% of total expenses, is crucial for maintaining profitability.

- Implementing automation, optimizing layout, and investing in training are effective strategies to reduce labor costs while enhancing operational efficiency.

- Utilizing data analytics and Warehouse Management Systems (WMS) enables better resource allocation, enhances decision-making, and helps track key performance indicators to identify cost-saving opportunities.

Smarter Warehouse Management Starts Here

From receiving to shipping, SphereWMS gives you real-time visibility and control over every square foot. See how it works for your operation.

Schedule Your DemoUnderstanding Warehouse Labor Costs

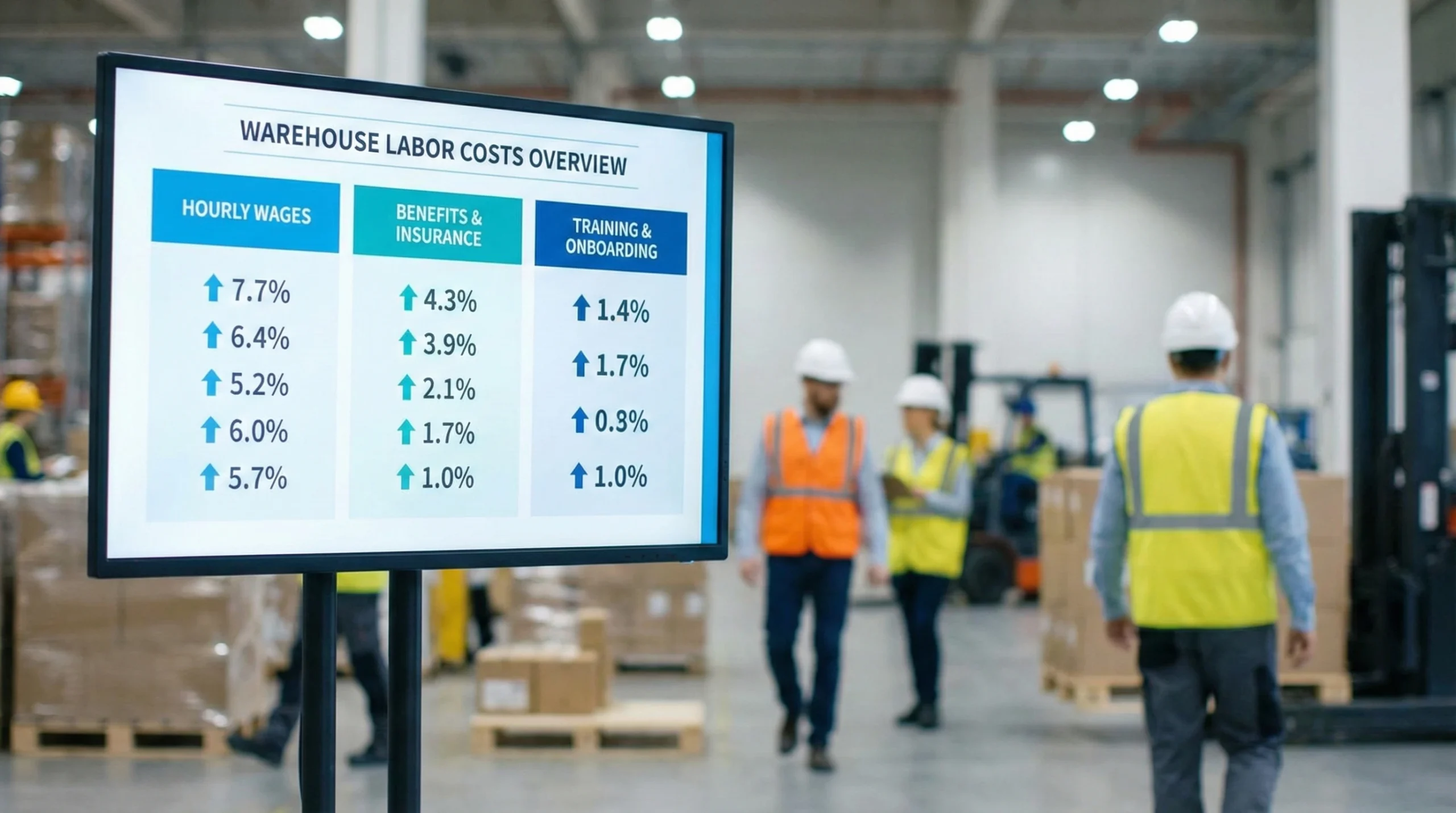

Warehouse labor costs are a critical component of overall warehouse expenses. These costs encompass wages, benefits, and additional training expenses for warehouse employees. Understanding these costs aids in effective budget planning and management. Larger warehouses often face higher personnel and maintenance expenses, which can significantly impact their operational budget.

Labor costs in warehouses also include ongoing expenses such as maintenance and insurance, which are necessary to keep the operations running smoothly. These warehouse costs can vary based on factors like the size of the warehouse, its location, and the materials used for construction. Breaking down and analyzing these components helps warehouse managers track spending and identify savings opportunities.

The Impact of Rising Labor Costs on Warehouses

The rise in economic activity and the boom in e-commerce have significantly increased the demand for warehouse labor. This surge has driven up labor costs, affecting logistics budgets, warehouse productivity, and facility headcount. Labor costs often account for 60% to 65% of total warehousing costs, making it a substantial part of overall warehouse expenses.

Managing rising costs is key to maintaining profitability. An actionable plan to reduce labor expenses is vital for effective warehouse management. Selecting, training, and retaining good employees helps control rising labor costs and ensures smooth operations.

Lowering labor expenses not only enhances financial health but also improves operational efficiency, enabling warehouses to process more orders with the same workforce.

Key Factors Influencing Warehouse Labor Costs

Several key factors influence warehouse labor costs, including location, proximity to distribution channels, and competitive labor markets. Warehouses in competitive labor markets often need to offer higher pay and better working conditions to attract qualified workers, contributing to increased labor costs. High employee turnover rates, which can range from 15-25% in distribution centers, also lead to increased training costs and workflow disruptions.

Reducing employee turnover is a critical priority for warehouse operators. It plays a significant role in maintaining operational efficiency. Lower turnover rates increase stability and decrease costs associated with hiring and training new staff. Addressing these factors enables warehouse managers to better manage labor expenses and improve operational efficiency.

Effective Strategies to Reduce Warehouse Labor Costs

Implementing strategies that balance efficient operations with a skilled workforce is necessary to reduce labor costs without affecting productivity. Optimizing processes and workflows, reorganizing inventory management, and improving picking and packing methods can significantly help reduce warehouse labor costs. Clear communication and feedback channels enhance employee morale and productivity.

This section delves into three key strategies: implementing automation and technology, optimizing warehouse layout and processes, and investing in training and development. Each strategy provides unique benefits and practical steps to streamline operations and lower labor costs.

Implement Automation and Technology

Automation and technology are game-changers in warehouse operations. Technologies like Goods-to-Person (G2P), Automated Storage/Retrieval Systems (AS/RS), and Autonomous Mobile Robots (AMRs) can significantly reduce labor needs in warehouses. Automated solutions such as conveyor belts, warehouse robotics, and automated storage and retrieval systems streamline operations and cut costs.

Although initial investments in automation technologies may increase labor costs, they ultimately lead to long-term savings. Automation minimizes human error, increases operational efficiency, and allows employees to focus on higher-value tasks, thus improving overall productivity and reducing labor costs.

Optimize Warehouse Layout and Processes

Optimizing warehouse layout and warehouse processes lowers labor costs. Analyzing every step in the process can identify areas for improvement, thereby streamlining workflows. Eliminating unnecessary steps and using data analytics to analyze order cycle times and picking routes can enhance efficiency and reduce labor expenses.

Warehouse slotting, which involves arranging inventory efficiently, enables fewer warehouse workers to pick more orders, thereby improving labor efficiency. Using ergonomic lifts can also reduce worker injuries and enhance overall safety in warehouse operations.

Optimizing warehouse space reduces costs by minimizing the need for larger facilities and lowering energy expenses.

Invest in Training and Development

Investing in training and development reduces labor costs and enhances warehouse productivity. Employee training is a significant factor contributing to warehouse operational expenses aside from wages. Providing consistent training and certifications for staff can help maintain high safety standards and operational efficiency.

Many organizations are increasing their supply chain and technical training efforts. Documenting job functions during training and quantifying expected output and results can improve training effectiveness and lead to cost reductions.

Effective training reduces employee turnover and ensures warehouse staff are well-prepared for their tasks.

Utilizing Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) play a pivotal role in managing warehouse operations. A WMS facilitates real-time tracking, which enhances inventory precision and reduces errors. Optimizing inventory levels with WMS helps prevent excess stock and minimize waste. The scalability of WMS allows businesses to adapt to growth without extensive system changes.

Integrating WMS with other systems streamlines operations by synchronizing inventory data across platforms. Data analytics in WMS allows warehouses to analyze historical data and market trends to forecast product demand accurately, optimizing inventory levels and reducing carrying costs.

Additionally, WMS enhances decision-making by providing insights and analytics to monitor stock levels and trends, improving accuracy, efficiency, and visibility of operations.

Leveraging Data Analytics for Cost Reduction

Data analytics is a powerful tool for reducing warehouse labor costs. Data analytics streamlines operations and increases productivity by pinpointing inefficiencies and optimizing resource allocation. Identifying labor utilization patterns allows warehouses to allocate resources efficiently and reduce overtime costs by identifying peak hours.

Tracking key performance indicators (KPIs) with data analytics provides valuable insights into warehouse operations, identifying areas needing improvement. This data-driven approach enables warehouse managers to make informed decisions, achieving significant cost savings while maintaining high operational efficiency.

The Role of Third-Party Logistics (3PL) Providers

Third-party logistics (3PL) providers can handle various functions including transportation, warehousing, and order fulfillment, enabling businesses to focus on core activities. Utilizing a 3PL provider enhances a business’s flexibility and scalability, allowing quick adaptation to changing logistics demands without the need for significant infrastructure investment.

Outsourcing logistics tasks to 3PL providers often results in significant cost reductions through optimized transportation routes and better negotiation of carrier rates. By collaborating with a 3PL, businesses can leverage existing infrastructure and specialized knowledge, streamlining logistics operations and improving overall efficiency.

Best Practices for Managing Warehouse Labor

Managing warehouse labor effectively requires a combination of accurate forecasting, performance metrics, and employee feedback. Effective labor forecasting helps align staffing with demand, managing and potentially lowering labor costs. Providing accurate feedback and performance metrics to employees is crucial for effective warehouse labor management.

Employee feedback mechanisms can identify improvement areas, and tracking performance visibility can boost productivity by up to 10%. Leadership accessibility to employees increases labor retention and improves throughput and efficiency.

Supporting employees and maximizing their potential are crucial for operational efficiency and cost reduction in warehouses.

Calculating Warehouse Labor Costs

Calculating warehouse labor costs involves tracking various components such as hourly wages, fringe benefits, employer-paid taxes, and other associated expenses. Labor costs, which can account for up to 65% of total warehouse fulfillment expenses, are a significant aspect of operational costs.

To calculate the total labor expense allocated to each item, track the number of items moved in a specific time frame and divide by total labor hours used. The throughput rate is determined by dividing the total items moved by total labor hours for a given period.

To find the labor cost per item produced, multiply the throughput time per item by the average hourly labor costs. Tracking key performance indicators offers valuable insights into warehouse operations and helps identify areas needing improvement.

The Benefits of Reducing Labor Costs

Reducing labor costs offers numerous benefits, such as better resource allocation and improved customer satisfaction through faster order fulfillment. Efficient labor cost management redirects funds to other critical areas, ensuring optimal resource use. Improvements in labor cost efficiency can also enhance employee morale, as streamlined processes reduce stress and workload.

Cost reductions can lead to significant savings and improved overall warehouse performance. By implementing effective labor cost reduction strategies, warehouses can achieve higher profitability and maintain a competitive edge in the market.

Optimize Labor Costs with SphereWMS

Reducing warehouse labor costs requires efficiency, accuracy, and streamlined processes—exactly what SphereWMS delivers. Our cloud-based Warehouse Management System (WMS) optimizes workflows, minimizes manual labor, and provides real-time visibility into inventory and operations.

With SphereWMS, you can:

- Automate order processing to reduce manual labor and errors

- Utilize barcode scanning for faster, more accurate picking and packing

- Optimize workforce allocation with real-time data and reporting

- Streamline inventory management to prevent overstocking and minimize handling time

- Integrate seamlessly with existing ERP, eCommerce, and shipping solutions

By implementing SphereWMS, warehouses can increase efficiency, reduce errors, and lower labor costs—without sacrificing service quality.

Ready to optimize your operations? Get started with SphereWMS today!

Summary

In summary, managing and reducing warehouse labor costs is essential for maintaining profitability and operational efficiency. By implementing strategies such as automation, optimizing warehouse layouts, and investing in training, businesses can significantly lower their labor expenses.

These cost-saving measures not only enhance productivity but also improve employee morale and customer satisfaction. By focusing on reducing labor costs, warehouses can achieve long-term success and maintain a competitive edge in the ever-evolving logistics landscape.

Take control of your warehouse labor costs with SphereWMS. Streamline operations, boost efficiency, and reduce expenses—get started today!

Frequently Asked Questions

What are the main components of warehouse labor costs?

The main components of warehouse labor costs are wages, benefits, training expenses, maintenance, and insurance. Understanding these elements is crucial for effective financial planning and management within a warehouse operation.

How can automation help reduce warehouse labor costs?

Automation effectively reduces warehouse labor costs by streamlining operations and minimizing human error, enabling employees to concentrate on higher-value tasks. This increased efficiency leads to significant cost savings.

What role does data analytics play in reducing warehouse labor costs?

Data analytics plays a crucial role in minimizing warehouse labor costs by identifying inefficiencies, optimizing resource allocation, and tracking performance metrics. This approach leads to improved productivity and cost savings.

Why is investing in training important for reducing labor costs?

Investing in training is crucial for reducing labor costs as it enhances employee efficiency, minimizes turnover, and ensures that staff are adequately equipped to perform tasks effectively. This ultimately leads to significant cost savings for the organization.

How do 3PL providers help in managing warehouse costs?

3PL providers effectively manage warehouse costs by leveraging specialized expertise and infrastructure, optimizing transportation routes, and negotiating favorable carrier rates, ultimately resulting in significant cost savings for businesses.