B2B fulfillment is the backbone of supply chains worldwide, ensuring that bulk goods, raw materials, and finished products reach businesses efficiently. Unlike B2C fulfillment, which focuses on individual consumers, B2B fulfillment involves high-volume orders, specialized shipping requirements, and complex contractual obligations.

Effective B2B logistics management is essential for businesses, as it directly impacts operational efficiency, customer satisfaction, and profitability. Companies must optimize every stage of the fulfillment process—from warehouse operations to shipping logistics—to stay competitive and meet rising expectations.

This guide explores the critical components of B2B fulfillment, the challenges businesses face, and best practices for optimizing fulfillment operations.

Understanding B2B Fulfillment and Its Unique Challenges

What Is B2B Fulfillment?

B2B fulfillment refers to the process of receiving, processing, and shipping orders between businesses. It involves multiple stakeholders, including suppliers, manufacturers, distributors, and retailers, each playing a crucial role in the supply chain.

Key Differences Between B2B and B2C Fulfillment

While B2B and B2C fulfillment share similarities, the operational differences are significant:

- Order Volume: B2B transactions involve bulk orders, often including pallets or truckloads of goods, whereas B2C fulfillment deals with individual consumer purchases.

- Order Complexity: B2B shipments require strict adherence to vendor agreements, specialized packaging, and scheduled replenishment plans.

- Payment Terms: B2B orders typically involve invoicing, net payment terms (e.g., Net 30, Net 60), and contract negotiations, whereas B2C sales are immediate transactions.

- Shipping & Logistics: B2B shipments often require freight services, multiple delivery locations, and compliance with industry regulations, making them more complex than B2C shipments.

Common Challenges in B2B Logistics

B2B fulfillment presents unique operational challenges:

- Bulk Shipping Costs: Freight optimization and load planning are crucial to minimizing transportation expenses.

- Order Accuracy: Errors in high-volume orders lead to costly delays, return processing, and lost business.

- Compliance Issues: Companies must adhere to regulatory requirements such as FDA, OSHA, and industry-specific shipping standards.

- Inventory Visibility: Poor inventory management can cause stockouts or overstocking, disrupting supply chains.

- Customer Expectations: B2B buyers expect high order accuracy, seamless order tracking, and fast turnaround times.

The Role of B2B Warehouse Management in Fulfillment Success

Warehouse Management Systems (WMS) for Optimization

A Warehouse Management System (WMS) is essential for streamlining B2B fulfillment. A well-implemented WMS enhances inventory visibility, optimizes picking and packing processes, and ensures accurate order fulfillment.

Key WMS features include:

- Real-Time Inventory Tracking: Reducing discrepancies and preventing stockouts.

- Automated Picking & Packing: Increasing efficiency and order accuracy.

- Barcode & RFID Scanning: Enhancing traceability and reducing human errors.

- Integration with ERP & TMS: Seamlessly connecting warehouse operations with order processing and transportation.

Inventory Management Strategies for B2B Fulfillment

Proper inventory management ensures that stock levels align with demand, reducing carrying costs and preventing supply chain disruptions.

- Demand Forecasting: Using historical data and AI-driven analytics to predict future demand.

- Just-in-Time (JIT) Inventory: Reducing excess inventory while maintaining the ability to fulfill orders promptly.

- Safety Stock Strategies: Ensuring backup inventory to prevent disruptions due to unexpected demand spikes.

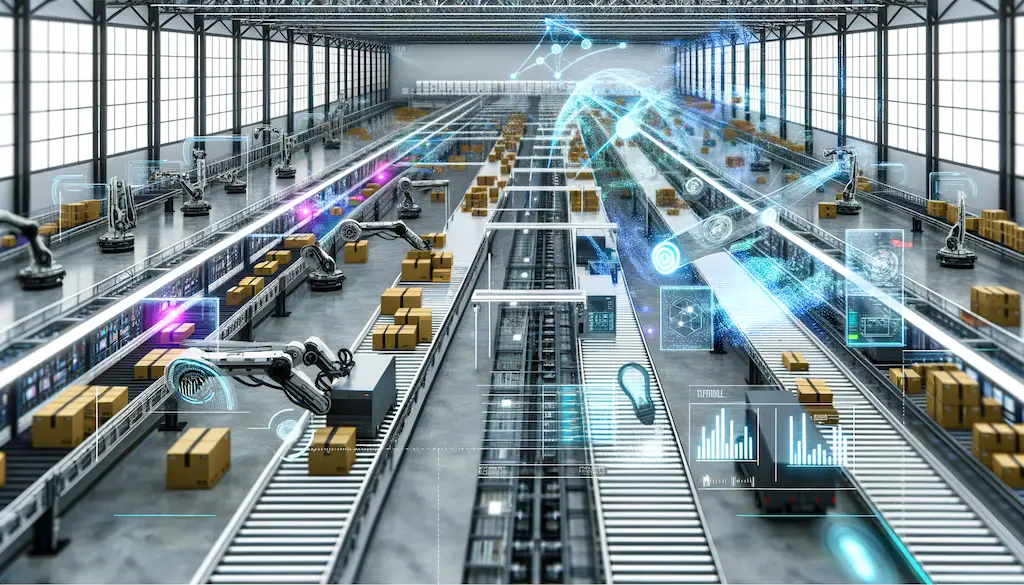

How Automation Enhances Accuracy in Warehousing

Automation plays a critical role in modern B2B fulfillment, reducing labor costs and improving accuracy:

- Automated Storage and Retrieval Systems (AS/RS): Enabling efficient storage and retrieval of products.

- Robotics in Order Picking: Improving speed and reducing errors.

- Machine Learning in Inventory Management: Optimizing stock levels based on predictive analytics.

B2B Order Fulfillment: Best Practices for Efficiency and Accuracy

The Step-by-Step Fulfillment Process

- Order Processing: Receiving, verifying, and entering customer purchase orders.

- Picking & Packing: Selecting the correct items and preparing them for shipment.

- Shipping & Delivery: Selecting the most cost-effective freight solution and tracking orders.

- Returns & Reverse Logistics: Managing product returns efficiently to maintain customer satisfaction.

Technology Integration for Seamless Fulfillment

Integrating fulfillment technology helps businesses reduce errors and improve operational efficiency.

- ERP Systems: Synchronizing inventory, order processing, and financial transactions.

- EDI (Electronic Data Interchange): Automating communication between businesses for faster order processing.

- Advanced Shipping Notifications (ASNs): Providing customers with real-time shipment updates.

Avoiding Common Pitfalls in B2B Fulfillment

- Inventory Discrepancies: Implementing cycle counting and real-time tracking to maintain accuracy.

- Delayed Shipments: Using AI-powered route optimization and proactive tracking to prevent delays.

- Poor Communication with Vendors: Automating order confirmations and shipment updates to improve coordination.

Navigating B2B Shipping and Delivery Solutions

Freight Options for B2B Fulfillment

Selecting the right freight method is crucial to controlling shipping costs and meeting delivery expectations:

- LTL (Less-than-Truckload): Ideal for smaller shipments that don’t require a full truckload.

- FTL (Full Truckload): Best for large orders, reducing per-unit shipping costs.

- Expedited Shipping: Prioritizing urgent shipments for faster delivery.

- Drop Shipping & Cross-Docking: Reducing storage costs and expediting order fulfillment.

Ensuring Compliance in B2B Logistics

B2B shipping often involves navigating regulatory challenges, including:

- Customs Compliance for Cross-Border Shipments

- FDA, OSHA, or Industry-Specific Requirements

- Proper Freight Classification & Labeling

Working with an experienced 3PL (third-party logistics) provider can simplify compliance and ensure smooth international trade.

The Impact of B2B eCommerce Logistics on the Supply Chain

How eCommerce is Transforming B2B Fulfillment

The rise of B2B eCommerce has forced businesses to rethink their fulfillment strategies, emphasizing speed, accuracy, and digital integration.

Key challenges include:

- Omnichannel Complexity: Managing online and offline order channels seamlessly.

- Bulk Order Processing: Ensuring cost-effectiveness while maintaining fast shipping.

Leveraging Third-Party Logistics (3PL) for Fulfillment

Many businesses partner with 3PL providers to streamline fulfillment and optimize costs. Benefits include:

- Scalability: Adjusting operations to meet fluctuating demand.

- Freight Cost Reduction: Leveraging 3PL-negotiated carrier rates.

- Warehousing & Distribution: Expanding geographic reach through multiple fulfillment centers.

Leveraging Technology for Smarter B2B Fulfillment

The Role of AI, IoT, and Data Analytics

AI-driven analytics, IoT sensors, and predictive modeling are poised to transform warehouse management in the coming years:

- AI-Powered Demand Forecasting: Poised to reduce overstocking and shortages.

- IoT-Enabled Inventory Tracking: Real-time monitoring of warehouse assets.

- Blockchain in Supply Chain Transparency: If implemented, can improve security and reducing fraud.

Cloud-Based WMS for Agility and Scalability

Cloud-based fulfillment software enables businesses to:

- Scale operations effortlessly

- Gain real-time insights into order and inventory data

- Enhance collaboration across supply chain partners

The Future of B2B Logistics: Emerging Trends

- Autonomous Delivery: Drones and self-driving trucks enhancing last-mile logistics.

- Sustainable Fulfillment: Carbon-neutral shipping and eco-friendly packaging initiatives.

- AI & Robotics Integration: Further streamlining warehouse and fulfillment operations.

How SphereWMS Optimizes B2B Fulfillment

B2B fulfillment demands precision, efficiency, and scalability—qualities that SphereWMS delivers through its robust cloud-based warehouse management system (WMS). Designed for 3PLs, eCommerce, and wholesale distribution, SphereWMS empowers businesses to streamline fulfillment operations, ensuring accuracy, speed, and compliance at every stage.

Key Benefits for B2B Fulfillment:

✅ Real-Time Inventory Visibility – Track stock across multiple warehouses to prevent shortages and overstocking.

✅ Automated Order Processing – Improve accuracy with barcode scanning, automated picking, and optimized packing workflows.

✅ Seamless Integrations – Connect effortlessly with ERP, eCommerce platforms, shipping carriers, and EDI systems to enable smooth transactions and communication.

✅ Advanced 3PL Billing & Compliance – Manage client-specific invoicing and adhere to industry regulations with ease.

✅ Scalable Cloud Solution – Adapt to fluctuating order volumes without compromising performance.

In the fast-paced world of B2B fulfillment, businesses can’t afford inefficiencies. SphereWMS provides the agility and control needed to meet customer expectations while reducing costs and enhancing operational efficiency.

Conclusion

Optimizing B2B fulfillment requires a strategic approach to warehouse management, order processing, and shipping solutions. By leveraging automation, predictive analytics, and cloud-based fulfillment platforms, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

Investing in smarter fulfillment strategies is key to staying ahead in today’s fast-evolving B2B supply chain landscape.

Ready to optimize your B2B fulfillment process? Contact us today to learn more about SphereWMS