COVID-19 is unbalancing both demand and supply. With unpredictable buyer demand, as well as supply chain shutdowns in China and some parts of the U.S., it can be hard to keep goods reliably on the shelves. This can cause the bullwhip effect and create problems all the way up the supply chain.

What is the Bullwhip Effect?

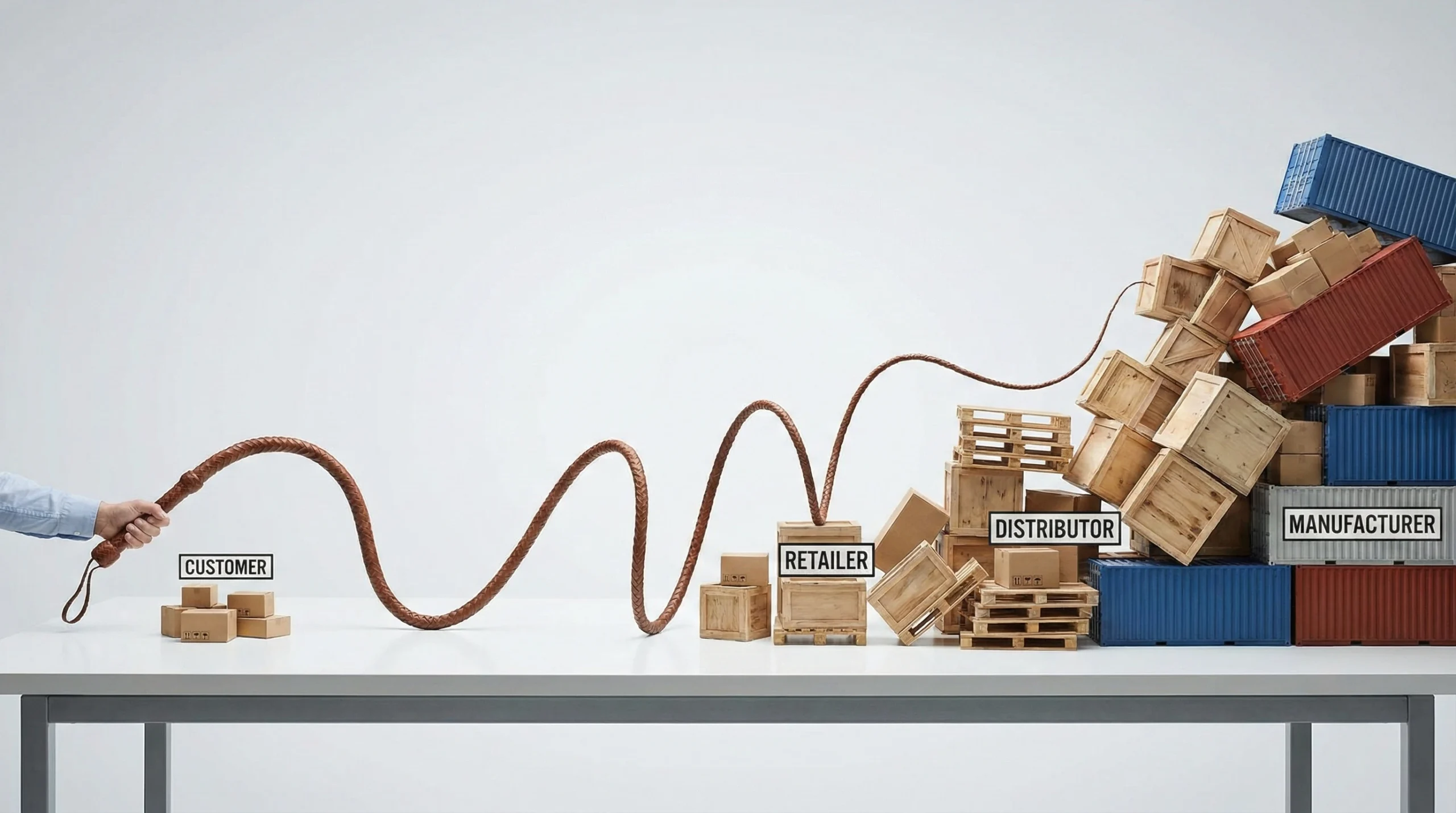

If you wave a whip, the amplitude of the motion increases towards the end of the whip. The bullwhip effect happens when a small variation in demand is perceived as a large one, causing production to change.

As an example: Early in the COVID-19 pandemic in the U.S., there was much hoarding of toilet paper (and much mockery of said hoarding). Shelves were emptied and retail outlets were forced to resort to rationing. By March 23, 70% of U.S. grocery stores were completely out of toilet paper. A few months later, some grocery stores were doing BOGO deals on toilet paper after manufacturers ramped up supply to meet a demand peak that, of course, was short-lived. That’s because people realized there was no real shortage … and they ran out of storage space.

Bullwhip effects can happen when retail and manufacturing aren’t talking to each other, but right now they are caused by unpredictable demand. Shortages of the weirdest things have shown up during the pandemic, including retail flour (there was never a shortage of flour, but there was a shortage of bags), vegetable seeds, yeast, and even bicycles.

What Problems Does the Bullwhip Effect Cause?

This supply chain phenomenon puts stress on production, warehousing, and transportation alike. It is exacerbated by lean and just-in-time inventory, where stores buy only what they need for a given week (indeed, many grocery stores do not have space to store more than that). Add in genuine supply-end shortages, and you end up with retail shortages, sometimes followed by surpluses after demand proves short-lived.

Both shortages and surpluses result in reduced income for manufacturers. You can’t sell what you don’t have, and if you can’t store what you can’t sell you have little choice but to drop the price.

Struggling with the Bullwhip Effect in Your Supply Chain?

Discover how SphereWMS equips you to manage and prevent the bullwhip effect. With our system, gain the real-time insights and inventory control needed to stabilize your supply chain against unexpected fluctuations and enhance operational resilience.

How Can You Protect Your Business From This Effect?

Dealing with the bullwhip effect involves improved automation and real-time understanding. Companies that invested in good ERP and supply chain planning systems have done better than those doing things “the way they’ve always been done.” Here are some things to consider:

- Real-time data aggregation is vital to spot trends. It’s equally important to understand how panic buying happens, what is being panic bought, and how it does and doesn’t affect overall demand.

- Communication with vendors and suppliers is vital. In more stable times, for example, manufacturers need to know about promotions and sales. In these times, it’s important to know who has the things you need and be able to switch suppliers (and customers) as needed.

- Onboarding new suppliers needs to be fast and easy, and needs to be done in a way which does not push aside existing suppliers. The more sources you have, the better.

- Adding more digital channels can help you deal with lower demand for a product, especially if that lower demand is local. For example, a store may have very low sales in an area where the infection rate is high, but may be able to ship the product to areas where the rate is lower in the meantime.

The key to surviving the bullwhip effect, both during the pandemic and moving forward, is having good inventory controls. SphereWMS offers warehouse management systems that can help you gather and use the real-time data you need to understand demand and avoid costly mistakes. To find out more, contact us today.

Real-World Bullwhip Effect Examples Across Industries

Understanding how the bullwhip effect manifests across different sectors helps warehouse managers recognize early warning signs and implement targeted mitigation strategies. Beyond the COVID-19 toilet paper shortage, several notable bullwhip effect examples demonstrate the widespread impact of demand amplification.

The automotive industry experienced a severe bullwhip effect in supply chain operations during the 2008 financial crisis. When consumer car purchases dropped by 40%, automakers drastically reduced orders to parts suppliers. Tier-1 suppliers then cut orders to Tier-2 suppliers by an even greater percentage, creating a cascading effect that shut down entire manufacturing networks. The recovery proved equally volatile—as demand slowly returned, supply shortages emerged because many suppliers had permanently closed or reduced capacity.

The electronics sector provides another compelling bullwhip effect example. When Apple releases a new iPhone, component suppliers often experience demand swings of 200-300% based on retailer forecasts and pre-order speculation. Memory chip manufacturers, in particular, struggle with these fluctuations since production capacity takes months to adjust. This creates a cycle where shortages lead to panic ordering, followed by oversupply when actual consumer demand stabilizes.

The fashion retail industry regularly demonstrates seasonal bullwhip effects. When weather patterns shift unexpectedly—such as an unusually warm winter—retailers slash orders for winter clothing. Textile manufacturers, operating with long lead times, continue producing based on earlier forecasts, resulting in massive inventory imbalances that ripple through the entire supply chain.

Measuring and Monitoring Bullwhip Effect Impact

Successful bullwhip effect management requires warehouse operations to establish clear metrics and monitoring systems that detect demand amplification before it creates supply chain disruptions. Key performance indicators help identify when normal demand variability crosses into bullwhip territory.

The primary metric for measuring bullwhip effects is the variance amplification ratio, calculated by comparing demand variability at different supply chain levels. A ratio above 1.2 typically indicates the presence of bullwhip effects, while ratios exceeding 2.0 signal severe amplification requiring immediate intervention. Warehouse management systems should track this ratio weekly across major product categories.

Order frequency analysis provides another critical measurement tool. When customer order patterns shift from regular, predictable intervals to sporadic, large-volume purchases, this signals potential bullwhip conditions. Modern WMS platforms can automatically flag accounts showing order frequency changes exceeding predetermined thresholds.

Additional monitoring indicators include:

- Inventory velocity changes: Sudden acceleration or deceleration in stock turnover rates

- Forecast accuracy degradation: When prediction models lose reliability across multiple SKUs simultaneously

- Supplier lead time volatility: Increasing variability in delivery schedules from upstream partners

- Cross-docking volume fluctuations: Unusual spikes or drops in direct-ship arrangements

Establishing automated alerts for these metrics enables warehouse managers to implement corrective measures before bullwhip effects cascade throughout the broader supply chain network.

Frequently Asked Questions

What is the bullwhip effect in supply chain management?

The bullwhip effect describes how small fluctuations in consumer demand can cause progressively larger swings in orders as they move upstream through the supply chain. A minor increase in retail sales might trigger disproportionately large orders to distributors, manufacturers, and raw material suppliers. This amplification leads to inventory imbalances, production inefficiencies, and increased costs throughout the supply chain.

What causes the bullwhip effect to occur?

Multiple factors contribute to the bullwhip effect including demand forecast errors, order batching practices, price promotions that encourage forward buying, and lack of supply chain visibility. Long lead times worsen the effect by requiring earlier ordering decisions based on uncertain forecasts. Poor communication between supply chain partners and inventory policies like order-up-to levels also amplify demand variability.

How can warehouses help mitigate the bullwhip effect?

Warehouses reduce bullwhip effects by providing real-time inventory visibility to supply chain partners through WMS integration. Implementing vendor-managed inventory programs allows suppliers to make replenishment decisions based on actual consumption data. Cross-docking and just-in-time delivery strategies reduce the need for large safety stocks that trigger order batching behavior.

What role does information sharing play in reducing demand amplification?

Sharing point-of-sale data and actual consumption information with upstream partners eliminates reliance on distorted order signals. Collaborative planning, forecasting, and replenishment programs align supply chain partners around common demand expectations. Real-time visibility into inventory levels throughout the chain enables more accurate and responsive ordering decisions.

How do technology solutions help prevent bullwhip effect problems?

Advanced analytics and demand sensing tools use machine learning to detect demand pattern changes faster than traditional forecasting methods. Supply chain visibility platforms connect trading partners with shared real-time data. Inventory optimization software recommends optimal stock levels and reorder points based on demand variability analysis. These technologies enable more responsive and accurate supply chain planning.