How Warehouse Management Systems Streamline Inventory Management

Warehouse Management Systems (WMS) have evolved from simple inventory tracking tools to comprehensive solutions that transform logistics operations across the supply chain. In today’s fast-paced distribution environment, effective inventory management represents one of the most critical challenges facing warehouse managers. A robust WMS provides the technological foundation needed to overcome these challenges by delivering real-time visibility, reducing manual processes, and optimizing stock placement. These sophisticated systems enable organizations to maintain precise inventory control while simultaneously supporting broader supply chain objectives like reduced carrying costs and improved order fulfillment.

Modern WMS platforms utilize barcode scanning, RFID technology, and IoT sensors to create a digital twin of physical inventory movements. This real-time tracking capability eliminates the inventory blind spots that plague traditional warehouse operations, ensuring that stock levels in the system accurately reflect what’s available on the shelves. For warehouse managers, this translates to fewer stockouts, reduced overstock situations, and the ability to make data-driven decisions about inventory replenishment. The system continuously monitors inventory levels against predetermined thresholds, automatically generating alerts when items need replenishment or when slow-moving products require attention.

Beyond basic tracking, advanced WMS solutions implement intelligent slotting optimization to determine the ideal placement of items within the warehouse. By analyzing order patterns, product characteristics, and picking sequences, the system can suggest optimal storage locations that minimize travel time and maximize space utilization. This sophisticated approach to inventory organization can dramatically reduce the time workers spend traveling through the facility, allowing them to fulfill more orders in less time while reducing physical strain and fatigue. For distribution centers handling thousands of SKUs, these efficiency gains compound to deliver significant operational advantages.

Cycle counting functionality embedded within WMS platforms has revolutionized traditional inventory auditing processes. Rather than conducting disruptive full-warehouse physical counts, the system enables continuous, targeted verification of inventory accuracy throughout normal operations. This approach not only improves inventory accuracy but also helps identify systematic issues that might be causing discrepancies. When paired with exception-based management tools, warehouse leaders can focus their attention on the specific items or locations experiencing accuracy problems rather than wasting resources on areas performing correctly.

Perhaps most valuable for supply chain professionals is the WMS’s ability to generate actionable insights from inventory data. Advanced analytics capabilities transform raw inventory movements into meaningful business intelligence about seasonal trends, product performance, and supplier reliability. These insights enable proactive decision-making rather than reactive responses to inventory challenges. For example, by analyzing historical demand patterns alongside current inventory levels, the system can recommend adjustments to safety stock levels that balance service requirements against carrying costs, helping organizations maximize working capital efficiency without compromising customer satisfaction.

Smarter Warehouse Management Starts Here

From receiving to shipping, SphereWMS gives you real-time visibility and control over every square foot. See how it works for your operation.

Schedule Your DemoEnhancing Order Fulfillment Through Automation

The integration of automation technologies within Warehouse Management Systems has fundamentally transformed order fulfillment operations across the logistics industry. By implementing automated workflows, distribution centers can process orders with unprecedented speed and accuracy while significantly reducing labor dependencies. Today’s sophisticated WMS platforms orchestrate complex automation systems—from conveyor networks and sortation equipment to autonomous mobile robots (AMRs) and goods-to-person technologies—creating synchronized fulfillment environments that outperform traditional manual operations. This orchestration layer ensures that automation investments deliver maximum value by coordinating equipment operations with human activities and broader warehouse processes.

Wave planning functionality within modern WMS solutions optimizes order batching and release timing to balance workloads and maximize throughput. The system analyzes incoming orders, available inventory, shipping deadlines, and resource constraints to create optimal picking waves that minimize congestion and equipment bottlenecks. For warehouse operators managing thousands of daily orders, this intelligent workload distribution prevents the productivity peaks and valleys that plague manual planning processes. By smoothing operational demand throughout the day, organizations can reduce overtime costs while still meeting shipping cutoff times and customer delivery promises.

Advanced picking methodologies supported by WMS automation deliver dramatic efficiency improvements compared to traditional paper-based processes. Zone picking, batch picking, and cluster picking strategies—all orchestrated through the WMS—allow warehouse teams to fulfill multiple orders simultaneously with minimal travel time. Mobile devices and wearable technologies guide pickers through optimized routes while confirming accurate item selection through barcode verification or voice confirmation. These digital picking technologies not only accelerate the process but also dramatically reduce errors, ensuring customers receive exactly what they ordered. For distribution centers handling e-commerce fulfillment, these accuracy improvements translate directly to reduced returns processing costs and higher customer satisfaction scores.

Packing and shipping operations benefit equally from WMS-driven automation through intelligent cartonization algorithms and integrated shipping systems. The WMS analyzes order contents, item dimensions, and carrier requirements to recommend the optimal packaging materials for each shipment, minimizing dimensional weight charges while ensuring product protection. Automated label printing, weight verification, and routing systems further streamline the shipping process, eliminating manual decision points that introduce delays and errors. When integrated with parcel carriers and transportation management systems, the WMS creates a continuous digital thread from order receipt through final delivery, providing full visibility to both operational teams and customers awaiting their shipments.

Beyond the immediate efficiency gains, WMS-powered automation delivers valuable data insights that support continuous improvement initiatives. The system captures detailed metrics on all automation components, identifying bottlenecks, equipment issues, and process inefficiencies that might otherwise go unnoticed. This performance data enables warehouse managers to refine automation configurations, adjust staffing levels, and optimize maintenance schedules to achieve peak operational performance. As organizations scale their operations, these data-driven insights ensure that automation investments continue delivering maximum value despite changing product mixes, seasonal fluctuations, and evolving customer expectations.

Leveraging Electronic Data Interchange (EDI) for Seamless Communication

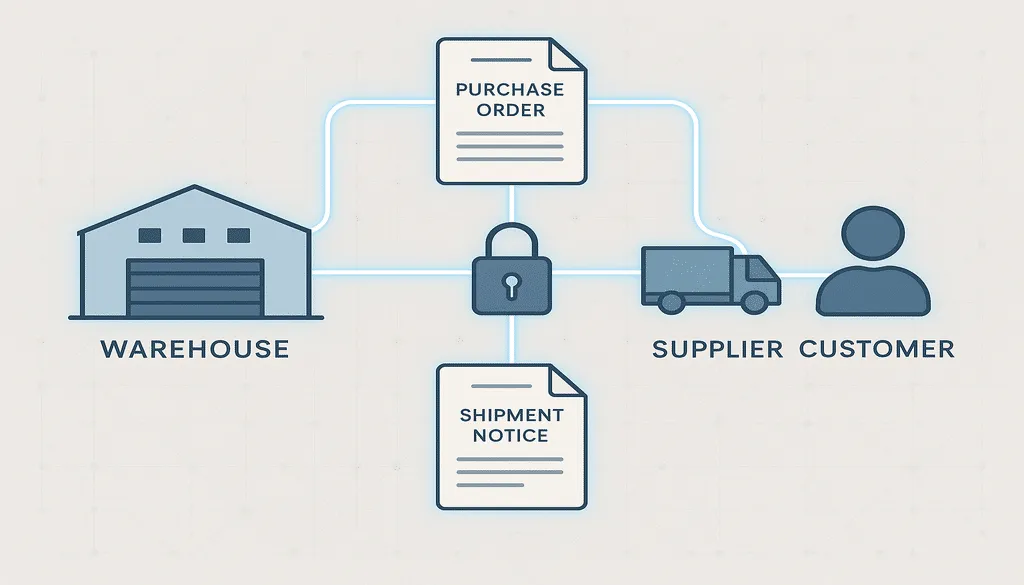

Electronic Data Interchange (EDI) integration within Warehouse Management Systems represents a transformative approach to supply chain communication that eliminates traditional information bottlenecks. By establishing standardized digital communication protocols between trading partners, EDI enables the automated exchange of critical documents like purchase orders, advance shipping notices, and invoices without manual intervention. This seamless data flow significantly reduces processing delays, eliminates costly data entry errors, and ensures that all supply chain participants operate from the same accurate information. For warehouse operations specifically, EDI integration means that inventory adjustments, order details, and shipping statuses flow automatically between systems rather than requiring manual updates across disconnected platforms.

The strategic value of EDI integration becomes particularly evident in complex distribution networks involving multiple suppliers, carriers, and customers. Rather than managing disparate communication methods for each trading partner, organizations can standardize their data exchange through EDI protocols managed by their WMS. This standardization dramatically simplifies onboarding new partners while ensuring consistent data quality across the network. When receiving inventory from suppliers, for example, advance shipping notices delivered via EDI provide precise details about incoming shipments before they arrive, allowing warehouse teams to plan labor resources and dock assignments optimally. This advanced visibility transforms receiving operations from reactive to proactive, improving throughput while reducing overtime costs.

Order processing efficiency improves substantially when EDI connects customer systems directly to the WMS platform. Purchase orders flow automatically into the system without manual entry, eliminating keystroke errors and processing delays that can compromise service levels. The WMS then processes these orders according to predefined business rules, prioritizing urgent shipments, allocating inventory, and initiating fulfillment workflows without human intervention. For high-volume operations processing hundreds or thousands of orders daily, this automation eliminates countless hours of administrative work while ensuring consistent execution. Additionally, EDI-enabled order acknowledgments provide customers with immediate confirmation that their orders have been received and validated, enhancing communication while reducing customer service inquiries.

Beyond operational efficiency, EDI integration provides critical data visibility that strengthens supplier relationships and improves inventory planning. Automatic transmission of inventory consumption data to suppliers enables vendor-managed inventory programs where restocking decisions occur collaboratively based on actual usage patterns rather than arbitrary reorder points. Similarly, performance metrics and quality data shared through EDI create accountability within the supply network, identifying opportunities for improvement while recognizing exceptional partner performance. This transparent, data-driven approach to supplier management transforms transactional relationships into strategic partnerships that deliver mutual benefits across the supply chain.

The compliance benefits of EDI integration cannot be overlooked in today’s complex regulatory environment. Many large retailers, government agencies, and automotive manufacturers mandate EDI compliance from their suppliers, making it a prerequisite for doing business. A WMS with robust EDI capabilities ensures organizations can meet these requirements while maintaining proper documentation for audit purposes. Additionally, the standardized nature of EDI transactions creates consistent data trails that simplify regulatory reporting and compliance verification. For organizations operating in highly regulated industries like pharmaceuticals or food distribution, these compliance capabilities represent essential risk management tools rather than mere operational conveniences.

Key Considerations When Implementing a Warehouse Management System

Successful Warehouse Management System implementation requires careful planning that begins with comprehensive business requirements definition. Before evaluating specific WMS solutions, organizations must document their current processes, performance challenges, and strategic objectives in detail. This thorough assessment identifies both operational pain points and future growth requirements that the WMS must address. Engaging stakeholders from across the organization—including warehouse staff, IT teams, finance, and customer service—ensures that the selected system will meet cross-functional needs rather than optimizing one department at the expense of others. This collaborative approach to requirements gathering not only improves system selection but also builds organizational buy-in that will be essential during implementation and adoption phases.

System integration capabilities represent perhaps the most critical technical consideration when selecting a WMS platform. Modern warehouse operations exist within complex technology ecosystems that typically include ERP systems, transportation management systems, e-commerce platforms, and automation equipment. The WMS must seamlessly exchange data with these systems through robust APIs, EDI connections, or native integrations to deliver its full value. Organizations should carefully evaluate each vendor’s integration approach, including available pre-built connectors, customization requirements, and the potential need for middleware solutions. Additionally, integration testing should feature prominently in the implementation plan to verify that data flows correctly between systems before the solution goes live, preventing costly disruptions to business operations.

Change management deserves as much attention as technical implementation when deploying a new WMS. Even the most sophisticated system will fail to deliver expected benefits if warehouse staff don’t understand how to use it effectively or resist adopting new processes. Successful implementations include comprehensive training programs tailored to different user roles, clear communication about how the system will improve daily work, and appropriate support resources during the transition period. Organizations should consider appointing “super users” from the warehouse team who receive advanced training and can provide peer support during implementation. These internal champions often prove more effective than external consultants at addressing day-to-day questions and encouraging adoption among their colleagues.

Data quality and migration present significant challenges that must be addressed early in the implementation process. The accuracy of inventory records, product master data, location configurations, and customer information directly impacts the new system’s performance from day one. Organizations should implement data validation and cleansing processes well before migration begins, establishing clear data governance standards and ownership for ongoing maintenance. Phased migration approaches often prove more successful than “big bang” conversions, allowing teams to validate data quality in controlled segments before committing the entire operation to the new system. This measured approach reduces risk while providing opportunities to refine migration processes based on early learning.

Post-implementation optimization represents the final consideration often overlooked in WMS planning. The initial go-live configuration rarely captures the system’s full potential value, as users need time to become proficient with basic functionality before leveraging advanced capabilities. Organizations should establish a formal process for capturing improvement opportunities, prioritizing enhancements, and implementing configuration changes as operational teams gain experience with the system. Additionally, maintaining regular communication with the WMS vendor ensures awareness of new features, available updates, and emerging best practices that might benefit the operation. This continuous improvement mindset transforms WMS implementation from a one-time project into an ongoing capability development initiative that delivers sustained competitive advantage.

Measuring Success: KPIs for Warehouse Management Systems

Establishing comprehensive key performance indicators (KPIs) provides the measurement framework necessary to quantify Warehouse Management System impact and guide ongoing optimization efforts. Effective WMS measurement strategies include both operational metrics that track daily execution and strategic indicators that align with broader business objectives. Order accuracy represents one of the most fundamental operational KPIs, measuring the percentage of orders fulfilled without errors in items, quantities, or configurations. This metric directly impacts customer satisfaction, return processing costs, and reputation in the marketplace. By tracking accuracy rates before and after WMS implementation—and continuing to monitor them over time—organizations can quantify quality improvements while identifying potential system configuration issues or training gaps that require attention.

Inventory management effectiveness can be measured through several interconnected KPIs that evaluate both accuracy and optimization. Inventory accuracy, typically measured through cycle counting programs, quantifies the percentage match between system records and physical counts. Inventory turnover rates measure how quickly inventory moves through the warehouse, with higher turnover generally indicating better working capital utilization. Days on hand calculations provide visibility into potential excess inventory situations by product category or supplier. When analyzed together, these inventory metrics help organizations balance service level requirements against carrying costs while validating that the WMS is delivering expected inventory management improvements. Regular review of these KPIs enables continuous refinement of min/max levels, safety stock calculations, and replenishment triggers managed through the WMS.

Labor productivity metrics demonstrate the efficiency impact of WMS implementation on warehouse operations. Units per hour, orders processed per person, and lines picked per hour provide quantifiable measures of workforce output that can be tracked at individual, team, and facility levels. When measured against established standards or historical performance, these metrics highlight productivity improvements directly attributable to WMS-enabled processes like optimized pick paths, improved slotting, and reduced administrative tasks. Additionally, analyzing productivity variation across shifts, departments, or individuals helps identify best practices that can be standardized across the operation. Organizations with labor management modules within their WMS can further enhance productivity measurement by comparing actual performance against engineered standards, creating accountability while recognizing exceptional performance.

Fulfillment cycle time metrics capture the speed dimension of warehouse performance, measuring how quickly orders move from receipt to shipment. Total order cycle time provides an end-to-end perspective, while component measurements like pick time, pack time, and dock-to-stock time highlight efficiency within specific process areas. These time-based metrics not only quantify internal performance improvements but also directly impact customer experience through faster delivery times. For operations supporting multiple channels or service levels, segmenting cycle time analysis by order type, customer category, or fulfillment priority provides more nuanced insights into performance variations. Organizations can leverage these metrics to identify bottlenecks, balance resources across departments, and establish realistic service level commitments based on actual operational capabilities.

Cost-focused KPIs complete the measurement framework by quantifying the financial impact of WMS implementation. Cost per order, cost per line, and cost per unit metrics normalize operational expenses against volume measures, enabling accurate comparisons despite fluctuating demand. Tracking these unit cost measures over time demonstrates the efficiency gains and scale economies achieved through WMS optimization. Additional financial metrics might include carrying cost reductions through improved inventory management, labor cost savings through productivity improvements, and transportation cost optimization through better load building and carrier selection. By connecting these financial metrics to specific WMS capabilities and process changes, organizations can calculate actual return on investment while building business cases for additional technology investments or system enhancements.

Conclusion

Implementing a comprehensive Warehouse Management System delivers transformative benefits across inventory management, order fulfillment, and supply chain communication. Through real-time visibility, advanced analytics, and process automation, these systems empower warehouse managers to make data-driven decisions that optimize operations while enhancing customer service. The integration of automation technologies orchestrated through the WMS platform enables unprecedented efficiency gains while reducing reliance on manual processes susceptible to error and variation. Meanwhile, EDI capabilities create seamless communication channels with suppliers, customers, and logistics partners, eliminating information delays and ensuring all stakeholders operate from accurate, up-to-date data.

Successful WMS implementation requires thoughtful planning that addresses technical requirements, integration needs, and change management considerations equally. Organizations must establish clear objectives, engage stakeholders across departments, and invest in thorough training to realize the system’s full potential. Once implemented, measuring success through comprehensive KPIs ensures continuous improvement and validates the return on technology investment. By tracking metrics like order accuracy, inventory turnover, labor productivity, and fulfillment cycle times, warehouse leaders can quantify improvements while identifying further optimization opportunities.

As supply chains continue evolving to meet changing customer expectations and market dynamics, warehouse management systems will remain essential tools for logistics professionals seeking operational excellence. Organizations that invest in robust WMS platforms—and develop the processes and expertise to leverage them effectively—position themselves for sustainable competitive advantage in an increasingly complex distribution landscape. By approaching WMS implementation as a strategic capability development initiative rather than merely a technology deployment, supply chain leaders can transform their warehouse operations into significant value creators for the broader organization.

Frequently Asked Questions (FAQ)

What are the main benefits of integrating automation and EDI into a Warehouse Management System?

Integrating automation and electronic data interchange (EDI) into a Warehouse Management System provides several key benefits. Automation improves accuracy, speeds up routine tasks like order picking and inventory tracking, and reduces manual labor. EDI enables seamless, real-time data exchange between suppliers, customers, and partners, minimizing paperwork and errors. Together, they help warehouse managers achieve faster order fulfillment, lower operational costs, and greater supply chain visibility, supporting better decision-making and improved customer satisfaction. Additionally, this integration creates scalability that allows operations to handle volume increases without proportional staff additions while standardizing communication protocols across the supply chain network.

How does EDI improve warehouse efficiency?

Electronic Data Interchange eliminates manual data entry by automatically exchanging business documents like purchase orders, invoices, and advance ship notices between trading partners. This reduces processing time from hours to seconds, eliminates transcription errors, and enables real-time visibility into order status. EDI integration with your WMS ensures inventory updates happen instantly when orders are received or shipped.

What warehouse processes benefit most from automation?

Receiving and putaway processes see significant gains from automated scanning and directed storage. Order picking benefits from pick-to-light systems, voice-directed picking, and goods-to-person robotics. Packing stations with automated cartonization and labeling increase throughput. Sortation systems speed up order consolidation. The best automation investments target your highest-volume, most repetitive tasks.

What is the typical ROI timeline for warehouse automation?

Simple automation like barcode scanning and mobile WMS typically pays back within six to twelve months through labor savings and error reduction. Conveyor systems and sortation equipment generally achieve ROI in two to three years. Advanced robotics and AS/RS systems may take three to five years but deliver ongoing labor savings and increased capacity that compound over time.

How do I choose between different automation technologies?

Start by analyzing your order profiles, throughput requirements, and labor costs. High-volume operations with consistent product sizes suit conveyor and sortation systems. Variable product mixes benefit from flexible solutions like autonomous mobile robots. Consider your growth projections, available capital, and integration requirements with existing WMS and ERP systems before selecting technology.