Warehouse safety is crucial, and OSHA provides clear guidelines to ensure a safe working environment. This article dives into key OSHA warehouse safety checklist items and best practices, explaining their importance and how to implement them effectively. Learn how these standards can help minimize risks and protect your workforce.

Key Takeaways

- OSHA plays a crucial role in warehouse safety by providing guidelines to reduce injury rates, which are particularly high in the supply chain industry.

- Key safety practices include proper training on PPE, implementing lockout/tag-out procedures, and maintaining clear aisles to prevent accidents.

- Regular inspections and employee training are essential for identifying hazards and enhancing safety measures in warehouses.

Smarter Warehouse Management Starts Here

From receiving to shipping, SphereWMS gives you real-time visibility and control over every square foot. See how it works for your operation.

Schedule Your DemoUnderstanding OSHA’s Role in Warehouse Safety

OSHA’s role in warehouse safety is both foundational and far-reaching. The agency’s primary mission is to promote the health and safety of workers across various industries, including the supply chain and distribution sector, which unfortunately experiences a higher rate of fatal injuries compared to other fields. This makes the implementation of rigorous safety measures absolutely essential.

Warehouse environments are particularly prone to safety hazards due to factors like increased automation, the rapid growth of e-commerce, and the inherently physical and fast-paced nature of the work. According to a Department of Labor report, the injury rate for full-time warehouse workers stands at a concerning 5.5 per 100 workers, underscoring the need for stringent safety protocols.

OSHA regulations help warehouses maintain safe operations and adhere to essential safety measures. Programs designed by OSHA help industries identify common hazards, injuries, and weaknesses, ultimately fostering a safer working environment for all warehouse workers. For example, keeping work areas clear not only boosts efficiency but also aligns with OSHA standard 29 CFR 1910.22, which addresses maintaining safe walking-working surfaces.

Key OSHA Warehouse Safety Guidelines

Adherence to key OSHA guidelines is crucial for maintaining a safe warehouse environment. One of the most critical aspects is ensuring that employees are well-trained in using proper personal protective equipment (PPE) to prevent respiratory issues and other injuries. OSHA requires employers to provide PPE free of charge and ensure that employees are trained in its correct use, in accordance with 29 CFR 1910.132. Regular training sessions on safe work practices suitable for both hot and cold conditions are also recommended.

Implementing a lockout/tag-out program is vital for the safe maintenance of equipment, preventing unexpected energization or startup of machinery during servicing. Regular inspections, including those for conveyors and mechanical handling equipment, are crucial for identifying potential hazards and ensuring compliance with OSHA regulations. Employers must also maintain proper lighting around these areas to enhance visibility and worker safety.

Moreover, maintaining clear aisles and passageways is essential to prevent falling hazards, a common cause of injury in warehouses. Following these guidelines fosters a safer, more efficient workplace, protecting workers and helping to avoid costly OSHA fines.

Common Safety Hazards in Warehouses

Warehouses are bustling hubs of activity, and with that comes a myriad of safety hazards. From falling objects and chemical exposure to unsafe walking surfaces, these hazards can pose significant risks to workers. Identifying these risks early and implementing mitigation measures is crucial.

Unsafe walking surfaces, in particular, can lead to slips, trips, and falls, which are common yet preventable incidents. Additionally, improperly stored materials are a frequent cause of workplace accidents, often leading to serious injuries.

The next sections will delve deeper into specific hazards such as forklift safety, material storage safety, and loading dock safety.

Forklift Safety

Forklifts are indispensable in warehouse operations but also pose significant risks if not handled properly. For this reason, forklift operators require specific training and certification, with OSHA mandating regular refresher courses to maintain competency. Following safe operation protocols is crucial to prevent accidents and injuries associated with forklifts.

Safety barriers help protect workers from hazards related to powered industrial trucks and other heavy machinery. These barriers, along with directional warning signs and proper personal protective equipment, help in maintaining a safe distance and preventing falling hazards in busy warehouse environments.

Material Storage Safety

Proper material storage is paramount in preventing injuries and fatalities in warehouses. Stable and securely stacked materials prevent accidents and ensure a safe working environment. Non-compliance with material storage rules can lead to fines and severe injuries, emphasizing the need for strict adherence to storage guidelines.

Safety must always be a primary consideration when transporting and storing materials. This includes maintaining adequate safe clearances, using mechanical handling equipment and equivalent materials handling equipment appropriately, and ensuring storage areas are organized and free from hazards like electrical cords and gassing batteries.

Loading Dock Safety

Loading docks are particularly hazardous, with nearly 25% of warehouse injuries occurring in these areas. Open loading dock doors pose significant risks, contributing to many workplace accidents. To mitigate these dangers, fall protection must be provided for any unprotected edges that are 4 feet or more above the ground, as specified in OSHA standard 29 CFR 1910.28. Installing guardrails approximately 42 inches high is one effective way to comply with OSHA’s fall protection requirements for loading docks.

Additionally, using appropriate signaling methods is crucial for safe operations at loading docks. Furthermore, research effective guardrail solutions that meet OSHA regulations to help prevent sliding and falling hazards.

Related: Boosting Warehouse Safety: Top Strategies for a Secure Workplace

Hazard Communication Standards

Handling hazardous chemicals in warehouses requires strict adherence to OSHA’s Hazard Communication Standard (29 CFR 1910.1200). Violations in this area pose significant risks, making it essential to ensure proper labeling and information dissemination. Each label must include a signal word, pictogram, hazard statement, and precautionary statements for the respective chemical.

Maintaining and updating Safety Data Sheets (SDSs) is the employer’s responsibility. These sheets must follow a specified format comprising 16 sections to convey comprehensive chemical safety information clearly. Educating workers about hazardous substances and their proper storage methods is also a crucial part of this standard.

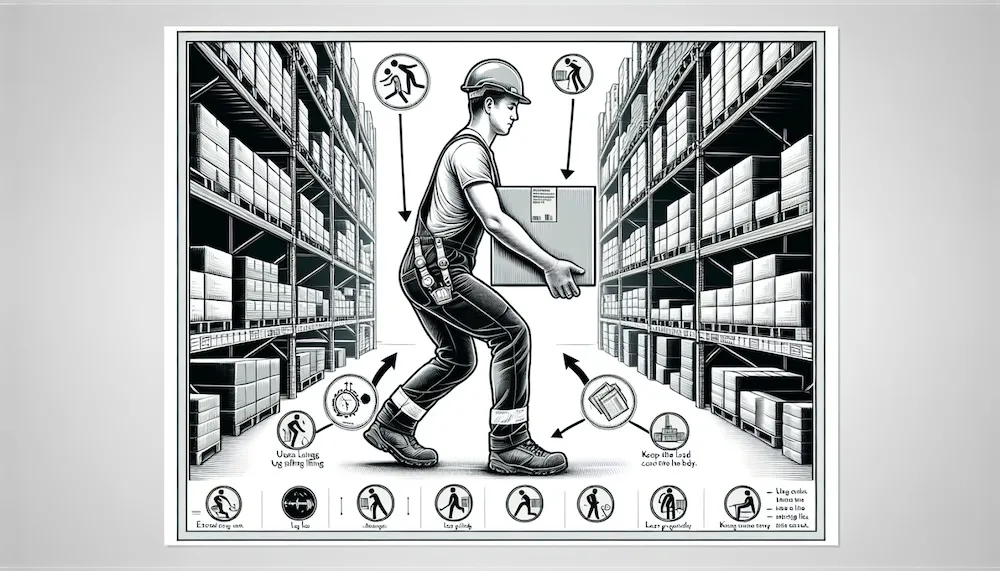

Ergonomics and Safe Lifting Practices

Ergonomics plays a significant role in reducing the risk of musculoskeletal disorders among warehouse workers. Utilizing smart lifting techniques, such as lifting within the power zone (from mid-thigh to mid-chest height), can help prevent a range of injuries. Mechanical devices like overhead hoists and forklifts can significantly reduce muscle stress during lifting.

While OSHA does not have specific ergonomics standards for general industry, employers are still required under the General Duty Clause (Section 5(a)(1) of the OSH Act) to provide a safe workplace free from recognized hazards that could cause serious injury. Planning, assessing load weight, and identifying aids are crucial for safe lifting practices. Additionally, ensuring adequate handholds and addressing environmental factors like temperature and lighting can further enhance lifting safety.

Warehouse Safety Checklist

A comprehensive warehouse safety checklist is essential for maintaining a safe work environment and staying in compliance with OSHA regulations. While OSHA does not provide an official, one-size-fits-all warehouse safety checklist, employers can create their own based on OSHA standards. These checklists help identify potential hazards, guide regular inspections, and ensure that safety protocols are followed throughout the warehouse.

Creating an OSHA-based checklist allows employers to focus on key safety areas, such as material storage, personal protective equipment (PPE), equipment operation, and emergency preparedness. It serves as a proactive tool to address hazards before they become serious issues and to reinforce ongoing employee training.

Frequent inspections using these checklists provide opportunities to assess current workplace conditions and make necessary adjustments to safety practices. This, in turn, enhances both the efficiency and accuracy of warehouse operations.

Below is an example OSHA warehouse safety checklist to help you get started:

Sample OSHA Inspection Checklist for Warehouses

- General Warehouse Environment:

- Are aisles, exits, and passageways free from obstructions?

- Are floors and walking surfaces clean, dry, and free of hazards (e.g., spills, debris)?

- Is there adequate lighting in all work areas and passageways?

- Are all work areas properly ventilated to manage dust, fumes, and vapors?

- Material Handling and Storage:

- Are materials stacked securely and not exceeding safe height limits?

- Are storage racks inspected regularly for damage or instability?

- Are heavy items stored at lower levels to reduce the risk of falling?

- Is proper equipment (forklifts, hand trucks) available and in good working condition for moving materials?

- Personal Protective Equipment (PPE):

- Is the appropriate PPE (gloves, eye protection, etc.) available for all tasks?

- Are employees trained on the correct use and maintenance of PPE?

- Is PPE storage easily accessible and properly organized?

- Forklift and Machinery Safety:

- Are all forklift operators trained and certified, with records up to date?

- Are forklifts inspected before each use for any operational issues?

- Are safety barriers in place around areas where forklifts and heavy machinery operate?

- Are warning signs and floor markings visible in forklift traffic areas?

- Loading Dock Safety:

- Are guardrails or other fall protection measures in place for open loading dock edges?

- Are wheel chocks or vehicle restraints used to prevent trucks from moving during loading and unloading?

- Is the dock area free from obstructions and well-lit for safe operation?

- Hazard Communication and Chemical Safety:

- Are all chemical containers properly labeled with hazard information?

- Are Safety Data Sheets (SDS) for all chemicals accessible to employees?

- Are employees trained on the safe handling, storage, and disposal of hazardous substances?

- Emergency Preparedness:

- Are emergency exits clearly marked and free from obstructions?

- Are fire extinguishers, first aid kits, and eye wash stations available and accessible?

- Is there an emergency action plan in place, and have employees been trained on it?

- Equipment Lockout/Tagout Procedures:

- Are lockout/tagout procedures in place to prevent unexpected equipment startup during maintenance?

- Are employees trained on the lockout/tagout process?

- Are lockout/tagout devices (tags, locks) available and properly maintained?

- Regular Inspections and Maintenance:

- Are scheduled safety inspections conducted regularly for warehouse areas and equipment?

- Are any hazards identified during inspections addressed promptly?

- Are maintenance records for all equipment kept up to date?

- Employee Training:

- Are employees trained on warehouse safety policies and procedures, including PPE use, emergency response, and equipment operation?

- Are training records maintained for all employees?

Importance of Regular OSHA Inspections

Regular OSHA inspections are vital in identifying and mitigating risk factors in warehouse operations. The OSHA warehouse safety checklist assists employers in systematically evaluating safety practices and making necessary improvements. Employers who use this checklist can enhance safety protocols and ensure compliance with OSHA standards.

These inspections include implementing fire prevention plans with adequate ventilation and effective sprinkler systems to maintain safety.

Investing in Employee Training

Employee training significantly enhances warehouse safety. OSHA requires forklift operators to receive formal training and recertification every three years. Comprehensive training programs can reduce the likelihood of accidents by up to 70%.

Employers are also obligated to train employees on the elements of new labels and the format of safety data sheets to enhance their understanding. Prioritizing warehouse health and safety training ensures that employees are well-prepared to handle various safety hazards in their work environment.

Maintaining Adequate Ventilation and Sprinkler Systems

Ventilation and sprinkler systems are critical for a safe warehouse environment. OSHA standards related to ventilation can be found in 29 CFR 1910.94, which covers ventilation requirements for managing contaminants and maintaining air quality. These systems must be designed to ensure adequate air circulation, reducing the concentration of airborne contaminants.

Regular maintenance and inspection of sprinkler systems are also required to ensure they are fully operational in case of fire emergencies, as outlined in OSHA’s 1910 Subpart E – Means of Egress. Together, these measures help create a safer and healthier work environment for all warehouse employees.

Summary

In conclusion, maintaining a safe warehouse environment requires a multifaceted approach that includes understanding OSHA’s role, adhering to key safety guidelines, and being vigilant about common hazards. Regular OSHA inspections, continuous employee training, and maintaining proper ventilation and sprinkler systems are all crucial elements in this safety equation.

By implementing these practices and utilizing tools like a comprehensive warehouse safety checklist, you can create a safer, more efficient workplace that not only complies with OSHA standards but also protects the well-being of your employees. Remember, a safe warehouse is a productive warehouse. With proactive measures and regular evaluations, safety can remain a top priority every day.

Boost Warehouse Efficiency with SphereWMS

Implementing OSHA safety guidelines is crucial for maintaining a safe warehouse environment. To further enhance your operations, consider using SphereWMS. Our warehouse management software optimizes inventory control, streamlines workflows, and ensures clear and organized storage practices—all of which contribute to a safer and more efficient workplace.

Ready to take your warehouse operations to the next level? Contact us today to learn more about how SphereWMS can support your safety and efficiency goals.

Frequently Asked Questions

Why is OSHA’s role in warehouse safety so important?

OSHA’s role in warehouse safety is vital because it establishes and enforces standards that help prevent injuries and fatalities in a high-risk environment. By implementing OSHA’s guidelines, warehouses can create safer workplaces, protect their employees, and reduce the likelihood of costly fines and legal issues.

What are some key OSHA warehouse safety guidelines?

Key OSHA warehouse safety guidelines include ensuring employees wear the appropriate personal protective equipment (PPE), following lockout/tag-out procedures during equipment maintenance, conducting regular equipment inspections, and keeping aisles clear of obstructions. Being proactive about these guidelines can significantly enhance workplace safety and efficiency.

What are common safety hazards in warehouses?

Common hazards in warehouses include falling objects, chemical exposure, unsafe walking surfaces, and improperly stored materials. Identifying and mitigating these risks is crucial for maintaining a safe working environment that complies with OSHA standards.

How often should employee training be conducted?

Employee training should be conducted regularly, with specific roles like forklift operators requiring formal training and recertification every three years as per OSHA guidelines. Ongoing training ensures employees stay up to date on safety practices and are prepared to handle potential hazards effectively.

Why are ventilation and sprinkler systems important in warehouses?

Ventilation and sprinkler systems are essential in warehouses because they maintain good air quality by managing hazardous fumes and provide critical fire safety measures. OSHA standards, such as 29 CFR 1910.94 for ventilation and 1910 Subpart E for fire safety, emphasize the importance of these systems in preventing health and safety hazards.